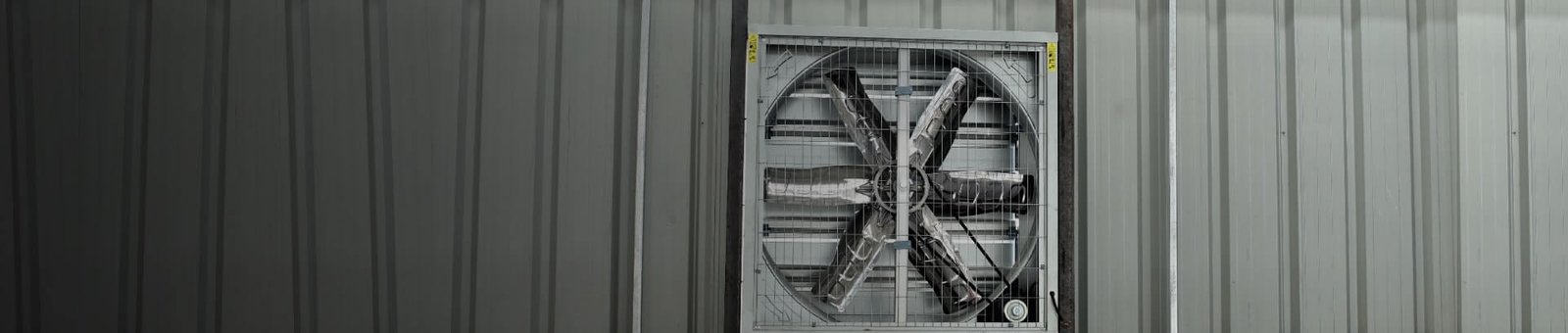

Industrial Exhaust Fans Manufacturer in India

Exhaust Fan

KRISSVENT offers a powerful range of heavy-duty industrial exhaust fans designed for commercial and industrial use. These commercial exhaust fans efficiently remove hot air, moisture, dust, and pollutants from large spaces like factories, warehouses, and industrial sheds, ensuring a safe, breathable atmosphere by expelling contaminated air and drawing in fresh air. Built for durability and high performance, our factory exhaust fans are ideal for demanding environments, providing reliable solutions for optimal airflow and temperature control.

Find the right number of exhaust fans with our easy-to-use Exhaust Fan Calculator

Product Attributions

Sleek Design

Sleek Design Minimal Noise

Minimal Noise Zero Maintenance

Zero Maintenance High Utility

High Utility High Durability

High Durability Easy Installation

Easy Installation High Performance

High Performance Light Weight

Light Weight Heavy Gauge GI Body

Heavy Gauge GI Body

Benefits

Exhaust Fan Products

Exhaust Fan

Model: KVS – 900

Dia(Blades - mm): 900

Blades Rotational Speed(r/min): 620

Air Flow(m3/hr): 30,000

Noise(Decibels): ≤70

Import Power W: 750

Rated Voltage V: 415

Height x Width x Thickness: 1000 x 1000 x 450

Industrial Exhaust Fan

Model: KVS – 1250

Dia(Blades - mm): 1250

Blades Rotational Speed(r/min): 439

Air Flow(m3/hr): 44,000

Noise(Decibels): ≤70

Import Power W: 1100

Rated Voltage V: 415

Height x Width x Thickness: 1380 x 1380 x 450

Factory Exhaust Fan (Direct Drive)

Model: KVS – 900

Dia(Blades - mm): 900

Blades Rotational Speed(r/min): 640

Air Flow(m3/hr): 33,000

Noise(Decibels): ≤70

Import Power W: 750

Rated Voltage V: 415

Height x Width x Thickness: 1000 x 1000 x 450

Small Industrial Exhaust Fan

Model: KVS – 300

Motor(W): 45

Net Weight(Kg): 4.2

Air Flow(m3/hr): 700

Noise(Decibels): ≤40

Rated Voltage V: 220

Frequency(Hz): 50

Height x Width x Thickness: 300 x 300 x 200

Hanging Plate Type Fan

Model: KVS - 1140

Dimensions(mm): 1140 x 1140 x 320

Power(Kw): 0.55

Voltage(V): 415

Blade Dia(mm): 1000

Speed(RPM): 700

Air Volume(m³/h): 32,500

Frame Material: Galvanised Plastic

Blade Material: 430

FAQs

An industrial exhaust fan is a large fan designed to remove stale air, heat, and moisture from industrial facilities.

The purpose of an industrial exhaust fan is to improve indoor air quality, reduce humidity levels, and remove contaminants and fumes from industrial processes.

Benefits of using industrial exhaust fans include improved air quality, increased ventilation, reduced humidity levels, and improved worker safety.

Industrial exhaust fans work by creating negative pressure that pulls stale air out of a space, venting it to the outside and drawing fresh air in.

The right size industrial exhaust fan for your space will depend on the size of the space, the air exchange rate required, and other factors. Consult with an industrial fan expert for guidance.

Yes, industrial exhaust fans can be used in conjunction with HVAC systems to improve air quality and ventilation in industrial spaces.

Industrial exhaust fans save energy by improving air circulation and reducing the need for heating and cooling systems to work harder, leading to lower energy consumption.

Installation of an industrial exhaust fan typically requires professional installation, including proper wiring, bracing, and anchoring to ensure safety and optimal performance.

The lifespan of an industrial exhaust fan can vary depending on usage and maintenance, but they typically last between 10 and 20 years.

Industrial exhaust fans can produce some noise, but many are designed to operate at a low decibel level to minimize disturbance to workers.

Yes, industrial exhaust fans can be used in residential spaces, particularly in areas with high humidity levels, such as basements and garages.

Regular maintenance includes cleaning the blades, checking motor function, inspecting wiring, and ensuring proper ventilation. Follow this – Maintenance checklist for optimal performance.

Regular maintenance for industrial exhaust fans includes cleaning the blades, checking the motor and belt, and ensuring proper wiring and safety measures are in place.

Industrial exhaust fans can improve worker safety by removing hazardous materials from the air, reducing humidity levels, and improving indoor air quality.

Industrial exhaust fans can reduce energy costs by improving air circulation and reducing the need for heating and cooling systems to work harder, leading to lower energy consumption.

Industrial exhaust fans are used in a variety of industries, including manufacturing, agriculture, pharmaceuticals, and automotive.

Features of industrial exhaust fans can include variable speed controls, weatherproofing, and explosion-proof designs for hazardous locations.

Industrial exhaust fans can improve indoor air quality by removing contaminants, reducing humidity levels, and improving ventilation.

The following industries/places can use industrial exhaust fans:

You can buy high-quality industrial exhaust fans from KRISSVENT, a trusted provider of efficient ventilation solutions. Explore our range here: KRISSVENT Exhaust Fans.

Installing an industrial exhaust fan requires proper mounting, electrical connections, and ventilation planning. It’s recommended to follow manufacturer guidelines or get professional installation from KRISSVENT for optimal performance.

Industrial exhaust fans come in various types, including wall-mounted, roof-mounted, and centrifugal fans, each designed for specific ventilation needs. Learn more about the types here Types of Exhaust Fans.